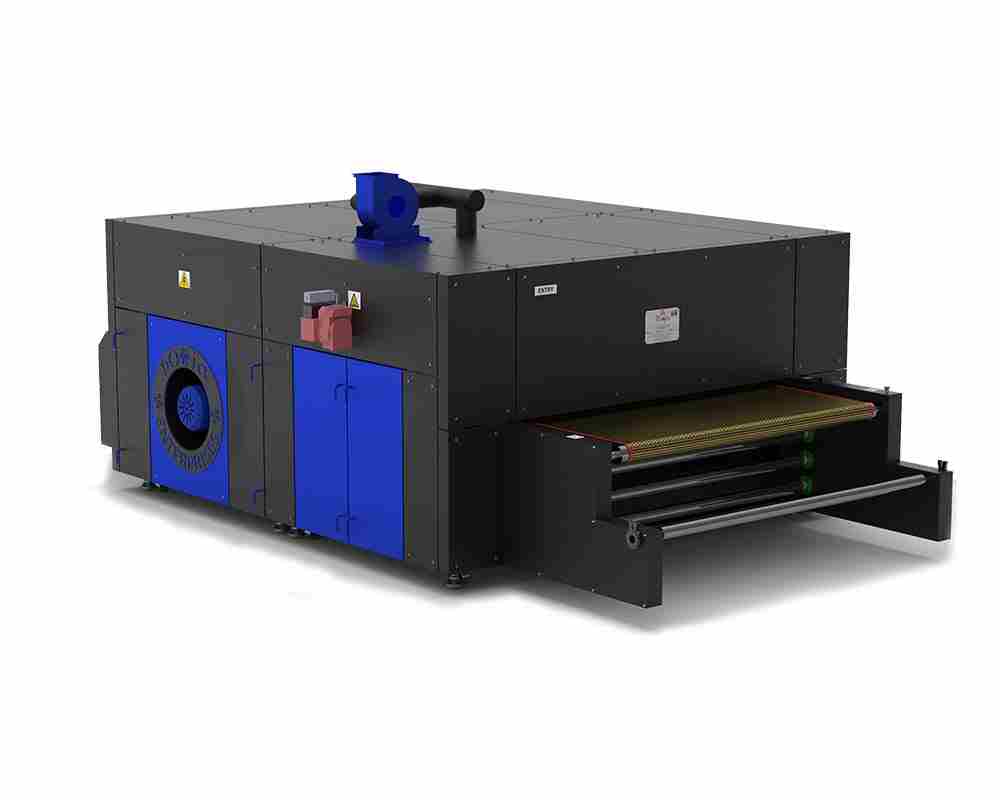

Digital printing quality isn’t decided only at the printhead. The dryer is where sharpness, handle, and fastness are either preserved or lost. At Pooja Enterprises, our Turbo dryers are engineered for consistent drying, precise fabric control, and low running cost—across reactive, pigment, disperse, and acid workflows. We’ve been building fabric-processing machines since 1991, with 35+ years of experience and 10,000+ machines delivered worldwide.

Why a purpose-built dryer matters

● Stable tones & edges: Even, repeatable drying preserves dot shape and avoids haloing/bleeding—critical after wet, high-load inks.

● Fabric integrity: Tension-managed conveyors keep the web relaxed to minimize elongation and shrinkage.

● Lower operating cost: Our machines are designed to be user-friendly, efficient, and economical for long, profitable runs.

Compatible with any printer—Italian, Indian, Chinese, you name it

Turbo dryers integrate cleanly with any digital printer brand and shop layout. We also offer same-as-printer branding when required by OEMs or large houses.

Choosing your Pooja Turbo dryer

Turbo Mini Series (compact, 3-pass drying, universal utility)

- Turbo Mini 0.5 — for sampling/smaller printers

• 80–90 m/h | 3 layers | 110–150 °C | Electric/Steam/Oil/Gas | Batching/Plaiter. - Turbo Mini 1 — popular with 16- & 24-head setups

• Up to 250 m/h | 3 layers | dual-heating options; batching/plaiter. - Turbo Mini 1.5 — when you need higher load or thicker fabrics

• 280–300 m/h | tuned sync & winding tension; dual-heating. - Turbo Mini 2 — for 32-head machines & longer dwell at lower temp

• 350–370 m/h | 3 layers | batching/plaiter.

3C (Triple Conveyor Control) customization

Upgrade any Mini with independent conveyors on all passes for relaxed fabric running—laser distance sensors + PLC/HMI for zero elongation and consistent drying. (Highly recommended to avoid production loss.)

Turbo Pro Series (precision sync for high-head printers)

- Turbo 1 Pro — compact, precise dryer for 32-head machines

• 400 m/h | 3 layers | Japanese sensor sync | dual-heating. - Turbo 2 Pro — for 64-head, export-grade throughput

• 700 m/h | 3 layers | Japanese sync | dual-heating. - Turbo 4 — for 128-head, precision at scale

• 1,000 m/h | batching + plaiter included.

Delivery & heating options across models

Batching / Plaiter / Both; and Electric, Steam, Thermic Oil, Gas; with dual-heating combinations available for energy optimization.

How requirements differ by chemistry (and how Turbo handles them)

- Reactive printing (pretreated cotton/viscose): Post-print dryer must evacuate moisture uniformly without distorting the web ahead of steaming + washing. Turbo’s 3-pass layout and optional 3C keep the web relaxed for crisp outlines before fixation.

- Pigment printing: After drying, pigments must be cured (binder polymerization). Pair Turbo dryers with our Turbo Cure units; continuous curing operates at ~165–180 °C based on dwell input.

- Disperse printing (polyester): Uniform drying before thermofix/steam helps avoid mottling; Turbo conveyors maintain even residence time pass-to-pass.

- Acid printing (nylon/silk): Lower temperature headroom with stable handling; Turbo’s 120–150 °C envelope with fine sync control suits delicate substrates.